Many warehouses, commercial buildings, and industries rely on PBR or “screw down” metal sheeting for economic roofs with superior hurricane resistance. PBR panels are attached close to roof decking, or steel purlins. Island Industries’ PBR systems are precisely engineered for use with our exclusive Lock-RivetTM fasteners. The durability of our metal roofs rely on the performance of each sturdy coupling. Here are some of their benefits.

1. No Rust

Our premium fasteners are all-aluminum so they never corrode. Most screws have a steel core plated with inexpensive zinc, or sometimes stainless steel. As the coating weathers, the steel core rusts quickly, causing leaks and compromising the integrity of the roof. Lock-RivetsTM are also compatible with PBR Galvalume sheeting, so the metals do not react with one another.

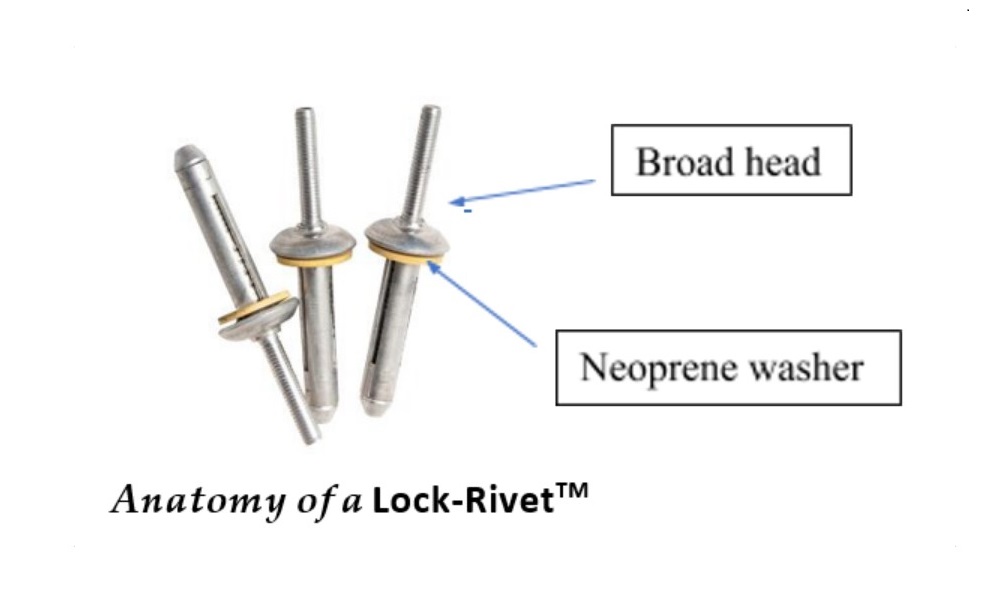

2. A broader head

The extended ¾” Lock-RivetTM factory head secures metal sheeting over a greater area, compared to ordinary screws which typically have a 7/16” cap.

3. Neoprene superpower

Under the domed head of a Lock-Rivet,TM protected from damaging solar rays, the snug Neoprene washer provides an airtight barrier. Invented by Dupont, neoprene was the world’s first synthetic rubber. The tough, oil-based composition also resists oils, solvents, and acids, making it ideal for industrial applications with chemical exposure–bottling companies, hangars, and chemical storage facilities. Wetsuits are formed of neoprene, proof of its strong, flexible, waterproof properties.

4. Tactical torque

When pulled by a custom rivet tool, the Lock-RivetTM stem breaks off when it reaches optimum tension. One of the most common installation mistakes is overtightened screws which damage rubber seals, creating vulnerability points in the roofing system. The Lock-RivetTM installation process prevents the sealing washer from “spinning-out” due to overtightening. These high performing fasteners significantly reduce roof maintenance and extend the life of your roofing investment.

Common Lock-Rivet roofing applications

4. Lock-Rivets will not loosen

The life cycle of a roof involves expansion and contraction. Continuous movement can cause screws to literally back out of their holes. But Lock-Rivets remains tight through endless cycles of thermal movement.

Metal Roof Inspection Reveals Screw Slippage

For over 3,000 years, rivets have helped man cross continents in ships and trains. Rivets fasten monuments like the Eiffel Tower and many renowned steel bridges. They helped win major wars, have transformed industries, even bonded spaceships that took us to the moon.

Always stronger than the metal surfaces they secure, the humble rivet represents classic design and enduring technology. Butler’s trademarked Lock-Rivet provides superior adhesion for metal roofs and buildings in coastal communities.

***

Tags:

- Lock-Rivet

- Metal roofs

- Fastener

- Screw

- Rivet

- Thermal movement

- Screw slippage

- Butler/Butler’s

- Butler’s Lock-Rivet

- Roofing

- Roof Systems PBR

- Screw-down

- Purlins/Battens

- Metal Sheeting

- Economic roofs

- Neoprene washer

- Rivet tool

- Durability

- Superior adhesion

- High performing fasteners

- Reduce roof maintenance

Suggested Blog URL:

h ttp://www.islandindustriesbs.com/blog/Butler-Lock-Rivet-Outperforms-Screws

Suggested Metadata:

Butler’s Lock-RivetTM Fastener Outperforms Screws (Five Advantages)